Unveiling the World of CNC Milling Cutters

CNC milling stands as a cornerstone in the realm of automated subtractive manufacturing, widely embraced across industries for its precision and versatility. At the heart of this technology lies the automated tool changer, a marvel that smoothly switches between diverse milling cutters, meticulously carving away material from workpieces with surgical-like accuracy. The choice of the right milling cutter for each specific task is not merely a matter of convenience; it is the linchpin that determines the efficiency, precision, and overall quality of the machining process.

This all - encompassing guide will embark on an in - depth exploration of the essential features of typical milling cutters, delve into the rich variety of milling tool types, examine the materials from which they are crafted, and offer practical insights into selecting the optimal cutter for your milling operations.

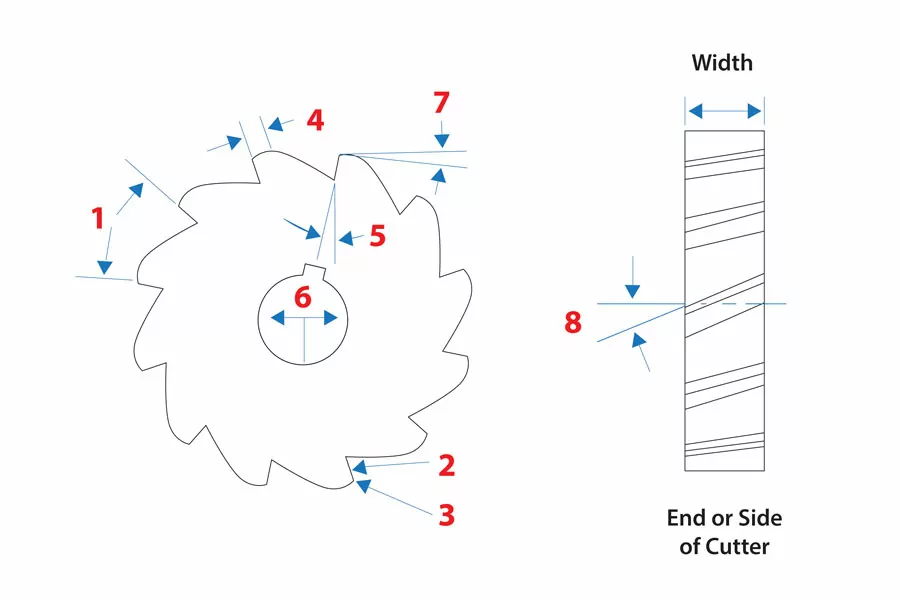

Anatomy of a Milling Cutter: Key Features

A standard milling cutter, upon close inspection, reveals several key features that are common to many of its counterparts:

Pitch: This refers to the angular spacing between the teeth, which is directly related to the number of teeth on the cutter. A larger pitch implies fewer teeth, while a smaller pitch indicates a higher tooth count.

Tooth Face: The forward - facing surface of the cutting edge, the tooth face plays a vital role in directing chips away from the cutting zone. This action ensures a smooth cutting process and prevents the accumulation of chips, which could otherwise disrupt the machining operation.

Cutting Edge: The angled portion of each tooth is responsible for the actual cutting of the material. Engineered to efficiently remove material while minimizing wear, the cutting edge is designed to maximize the tool's lifespan.

Land: The flat surface behind the cutting edge, the land provides support and reinforces the tooth during the cutting process, enhancing the overall strength and stability of the cutter.

Rake Angle: Defined as the angle between the tooth face and the cutter's centerline, the rake angle significantly influences chip formation and cutting efficiency.

Hole Diameter: This is the diameter of the central hole, which determines the size of the arbor or spindle required to mount the cutter securely.

Primary Clearance Angle: Measured from a line perpendicular to the cutter's centerline at the cutting edge, this angle, usually ranging from 5 to 7 degrees, prevents the tooth from rubbing against the workpiece and facilitates the evacuation of chips.

Spiral or Helical Teeth: These teeth, arranged in a helical pattern, are commonly found on wider cutters (over 3/4 inch). They offer a smoother cutting action, reduce cutting forces, and improve the surface finish, especially when working on interrupted surfaces or uneven materials.

Diverse Types of Milling Cutters

Milling cutters come in an extensive array of shapes, sizes, and designs, each tailored to specific cutting tasks. Familiarizing oneself with these different types is essential for making an informed choice when selecting a cutter for a particular project.

End Mill Cutters

End mill cutters are highly versatile and among the most commonly used milling tools. Resembling drill bits, but with a crucial difference, end mills have cutting edges on both the end and the side, enabling them to perform both axial and lateral cutting. They are widely employed in various machining tasks, including plunging, slotting, profiling, drilling, and contouring.

Square End Mills: Also known as flat end mills, these have a flat end with sharp 90 - degree cutting edges. Ideal for general - purpose tasks such as plunging, profiling, and slotting, they are particularly useful for creating square - bottomed slots and pockets.

Ball End Mills: Featuring a hemispherical tip with rounded cutting edges, ball end mills are commonly used for 3D contouring. They excel at fine finishing passes on complex geometries or curved surfaces, such as molds and dies.

Corner Radius End Mills: Similar to square end mills, but with a rounded radius at the cutting corners instead of sharp angles. This design helps prevent stress concentrations, reduces the risk of corner chipping, and extends the tool's lifespan. They are perfect for creating filleted edges and are often used to produce small - radius transitions on both internal and external part edges.

Rounding End Mills: Designed with a specific radius along the cutting edges, these are typically used for machining rounded edges on the exterior of parts. They are frequently used for deburring and enhancing the safety and appearance of part edges.

Undercutting End Mills: Also called lollipop cutters, they have a spherical or curved cutting head. Their extended neck allows them to reach deep or hard - to - access areas that standard end mills cannot, making them suitable for machining undercuts, grooves, overhangs, or the backside of interior walls.

Face Milling Tools

In contrast to end mill cutters, which perform both end and side cutting and are mainly used for detailed work, face milling tools focus on end cutting to machine large, flat surfaces. With a larger diameter, face mills cut horizontally and can efficiently cover broad surface areas. They often feature multiple replaceable inserts, enabling rapid roughing of large surfaces and providing a smooth finish when using finishing inserts.

Slotting and Grooving Cutters

Slotting and grooving cutters are specialized tools for cutting slots, grooves, and keyways, which are essential for accommodating inserted components. Usually thin and disc - shaped or with specialized geometries, they allow for narrow and precise cuts.

T - slot Cutters: These have teeth perpendicular to the outside diameter and are specifically designed to cut T - shaped slots, which are commonly used to securely hold bolts, fixtures, or other components that require precise mounting and assembly.

Woodruff Cutters (Keyway Cutters): Small, disc - shaped cutters used for cutting keyways, which are grooves that connect rotating parts like shafts and gears, preventing slipping and ensuring a secure fit.

Slitting Saw Cutters: Characterized by their thinner blades, these cutters are often used for precise slitting, parting, or cutting deep, narrow grooves.

Form Milling Cutters

Form milling cutters are designed with specific profiles, allowing for the precise machining of intricate contours in a single pass. They are highly efficient for manufacturing gears, threads, and other complex parts.

Gear Milling Cutters: Used to produce various types of gears, including spur gears (with straight teeth), helical gears (with angled teeth), and bevel gears (with conical teeth).

Convex Milling Cutters: Ideal for machining outward - curved, rounded profiles on a workpiece, typically for semi - circular or arc - shaped contours.

Concave Milling Cutters: These have a rounded, inward cutting edge that enables them to create smooth, concave profiles or grooves.

Thread Milling Cutters: Employed to produce both internal and external threads in a workpiece. Unlike traditional threading operations like tapping, which are usually done on drilling machines, thread milling offers more precise control over thread diameter and pitch, providing greater stability and fewer limitations in different working environments.

Fly Cutters

Fly cutters and face mills both machine flat surfaces on a workpiece, but they differ in design and application. Fly cutters typically have a single or double cutting tool mounted on an arbor and are more cost - effective. They are well - suited for light - duty milling, prototyping, and use on manual milling machines. When operated at lower speeds with light cuts, fly cutters can produce excellent surface finishes, although they are not suitable for heavy - duty or high - speed machining.

Materials of Milling Cutters

Milling cutters are made from a variety of materials, each with its own set of advantages tailored to different machining requirements.

High - Speed Steel (HSS): Named for its ability to retain hardness and wear resistance at high cutting speeds, thanks to alloying elements such as molybdenum, tungsten, chromium, and sometimes vanadium or cobalt. However, HSS starts to lose its hardness at around 600 - 650°C, making it more suitable for general - purpose milling of softer materials like aluminum, steel, and plastics. It is commonly used for tools that need to stay sharp under moderate cutting conditions, and coolants are often used to prevent overheating and extend the tool's life. Adding cobalt (5 - 8%) creates HSCO, which offers improved heat resistance and hardness, making it suitable for more demanding applications.

Cemented Carbide: A composite material consisting of tungsten carbide (WC) particles bonded with a metal binder, usually cobalt. The carbide provides extreme hardness, while the binder adds toughness to reduce brittleness. This combination results in a material that is highly hard, wear - resistant, and capable of withstanding cutting temperatures up to 1000°C. Compared to HSS, cemented carbides are much harder and perform better at higher cutting speeds, making them ideal for machining hard materials such as stainless steel, cast iron, and non - ferrous metals. They are widely used in milling tools, drills, and inserts.

Ceramics: Ceramic milling cutters are even harder and have better heat resistance than cemented carbides, but they lack in toughness. They are mainly used in high - speed machining, dry machining, and the machining of hard and heat - resistant materials like hardened steels, cast iron, and superalloys. Due to their brittleness, ceramic tools are best used for continuous cutting operations rather than interrupted cuts.

Polycrystalline Diamond (PCD): Made from diamond particles, PCD is one of the hardest materials available, giving it exceptional wear resistance, although it is brittle. PCD tools are primarily used for machining non - ferrous metals such as aluminum and copper, as well as composites like carbon fiber and fiberglass, and plastics. However, they are not suitable for machining steel because the diamond can react chemically with the carbon in steel at high temperatures, causing premature tool failure. Additionally, PCD tools are quite expensive.

Coated Carbide: Coated carbide tools consist of a cemented carbide base with one or more layers of wear - resistant materials, such as titanium nitride (TiN), titanium carbonitride (TiCN), aluminum oxide (Al2O3), or aluminum titanium nitride (AlTiN). These coatings enhance heat resistance, hardness, and reduce friction, allowing the tool to cut harder materials at higher speeds and temperatures more efficiently.

Choosing the Perfect Milling Cutter

Selecting the right milling cutter involves a comprehensive assessment of multiple factors, taking into account the specific requirements of your milling operations.

Workpiece Material and Machining Needs

Workpiece Material: The choice of milling cutter should be based on the material being machined. For harder materials like stainless steel, titanium, or hardened alloys, cemented carbide tools are the preferred option due to their superior hardness and wear resistance. Softer materials like aluminum or copper can be efficiently machined using High - Speed Steel (HSS) cutters, which are more affordable but have a shorter lifespan.

Machining Requirements: Evaluate the specific needs of your project, including precision, surface finish, and production efficiency. Coarse - toothed cutters are suitable for roughing operations to quickly remove large amounts of material, while tools with more teeth and finer cutting geometries are better for fine finishing to achieve smoother results.

Machine Tool and Machining Conditions

Machine Tool Compatibility: Ensure that the power requirements of the tool match the capacity of the milling machine. Larger tools generally require more power, and smaller tools should be compatible with the machine's maximum rotational speed for efficient high - velocity cutting. Also, confirm that the machine's spindle and clamping systems can adequately support the size and design of the tool.

Clamping and Stability: Check the clamping capacity of the machine and the stability of the fixture. A proper fixture setup helps reduce vibrations and ensures that the tool maintains consistent contact with the workpiece during the cutting process.

Specific Cutter Parameters

Cutter Diameter: The diameter of the milling cutter is crucial for both speed and precision. A larger diameter cutter can remove material more quickly but may not be suitable for intricate work or tight spaces. For face milling, the formula D = 1.5d (where “d” is the spindle diameter) can be used as a guideline. In less rigid setups or when working with smaller parts, a smaller diameter tool is often preferred to maintain control and reduce deflection.

Number of Teeth (Flutes): The number of teeth affects the smoothness of the cutting process and the power requirements. Fewer teeth are ideal for roughing operations, while more teeth are better for finishing. However, more teeth can lead to reduced chip evacuation, so proper coolant and swarf removal measures must be considered.

Tool Coating: Coatings such as Titanium Nitride (TiN) or Aluminum Titanium Nitride (AlTiN) can enhance the tool's wear resistance, heat tolerance, and lifespan, especially when working with abrasive materials or at high speeds. Although coated tools are more expensive upfront, their performance in harsh conditions and extended lifespan may justify the cost, depending on the job requirements.

Cutter Geometry: Parameters like rake angle, cutting edge inclination, and relief angle should be selected based on the cutter and workpiece materials and the machining conditions. A steeper rake angle is suitable for softer materials like aluminum, while harder materials like steel may require a shallower angle for better cutting stability.

Tool Blade Selection: Pressed blades are more cost - effective for roughing operations, while grinding blades offer better dimensional accuracy and smoother surfaces for finishing. Always ensure that the blade type matches the machining task to optimize performance.

Economics and Feasibility

Finally, when selecting a milling cutter, it is essential to balance cost, tool life, and replacement frequency. While imported cutters may offer better performance and longer life, domestic tools can be more cost - effective for smaller projects or less demanding tasks. In some cases, investing in a higher - performance tool can lead to significant long - term savings by reducing downtime and replacement costs, especially in large - scale production runs.

Conclusion

Milling cutter tools play a pivotal role in achieving versatile milling operations and creating products with diverse shapes. Their wide range of types allows them to adapt to different cutting tasks. If you are still unsure about selecting the right tool, consulting an expert for professional advice is recommended.

At HL Parts, our expert engineers are ready to help you select the best milling cutters for your project. We also offer customized manufacturing services and comprehensive manufacturing solutions to meet all your needs, including CNC machining services, 3D printing, rapid prototyping, and more. Upload your files and let’s get started!